At Aeron Pacific, our sheet metal fabrication capabilities cover a spectrum of services, This versatile manufacturing technique is commonly used in industries such as automotive, aerospace, construction, electronics, and more. Here’s an overview of the key aspects of sheet metal fabrication:

Types of Sheet Metal – Common materials include steel, aluminium, stainless steel, brass, and copper.

Sheet Thickness – The thickness of the sheet metal is a crucial factor and can range from thin foils to thicker plates.

Types of Sheet Metal – Common materials include steel, aluminium, stainless steel, brass, and copper.

Sheet Thickness – The thickness of the sheet metal is a crucial factor and can range from thin foils to thicker plates.

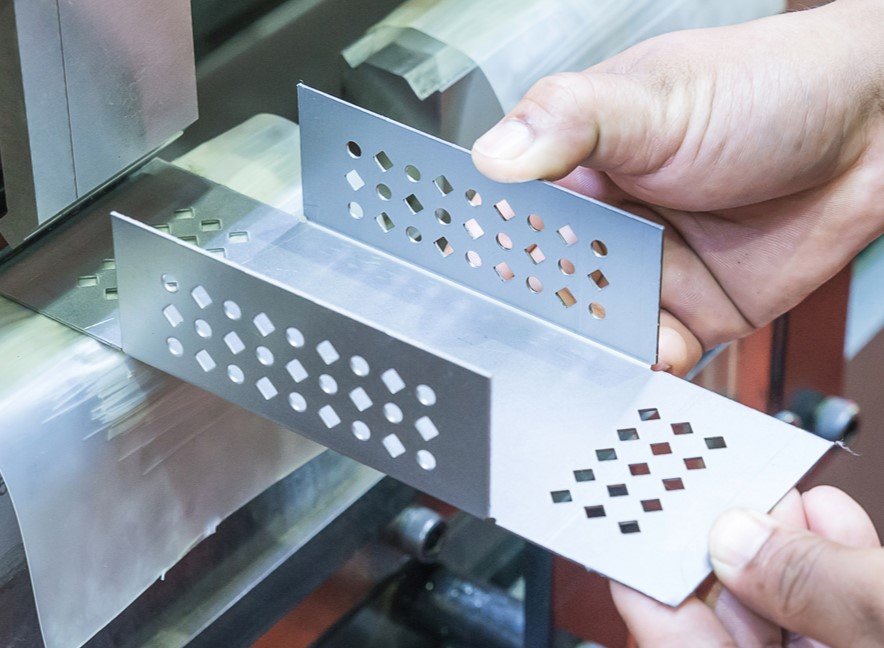

Bending – Sheets are bent into specific shapes using press brakes or other bending equipment.

Rolling – Curved or cylindrical shapes are formed by passing the sheet through rollers.

Bending – Sheets are bent into specific shapes using press brakes or other bending equipment.

Rolling – Curved or cylindrical shapes are formed by passing the sheet through rollers.

Fasteners – Bolts, nuts, screws, and other fasteners are used to assemble sheet metal components.

Adhesives – Some applications use adhesives for joining sheets.

Surface Treatment – Processes like painting, powder coating, or plating improve aesthetics and provide corrosion resistance.